At Electroforce, we are proud to offer high-volume tight-tolerance metal stamping services that excel in precision and quality.

Our manufacturing processes and industry-leading technology enable us to create innovative solutions that meet the complex component needs of our customers.

Our metal stamping process begins with the use of high-quality progressive dies, which are designed to ensure consistency and accuracy. We utilize leading precision metal stamping presses such as Bruderer, Godrej, Sutantra, and Ruby, with sizes ranging from 10 tons to 50 tons.

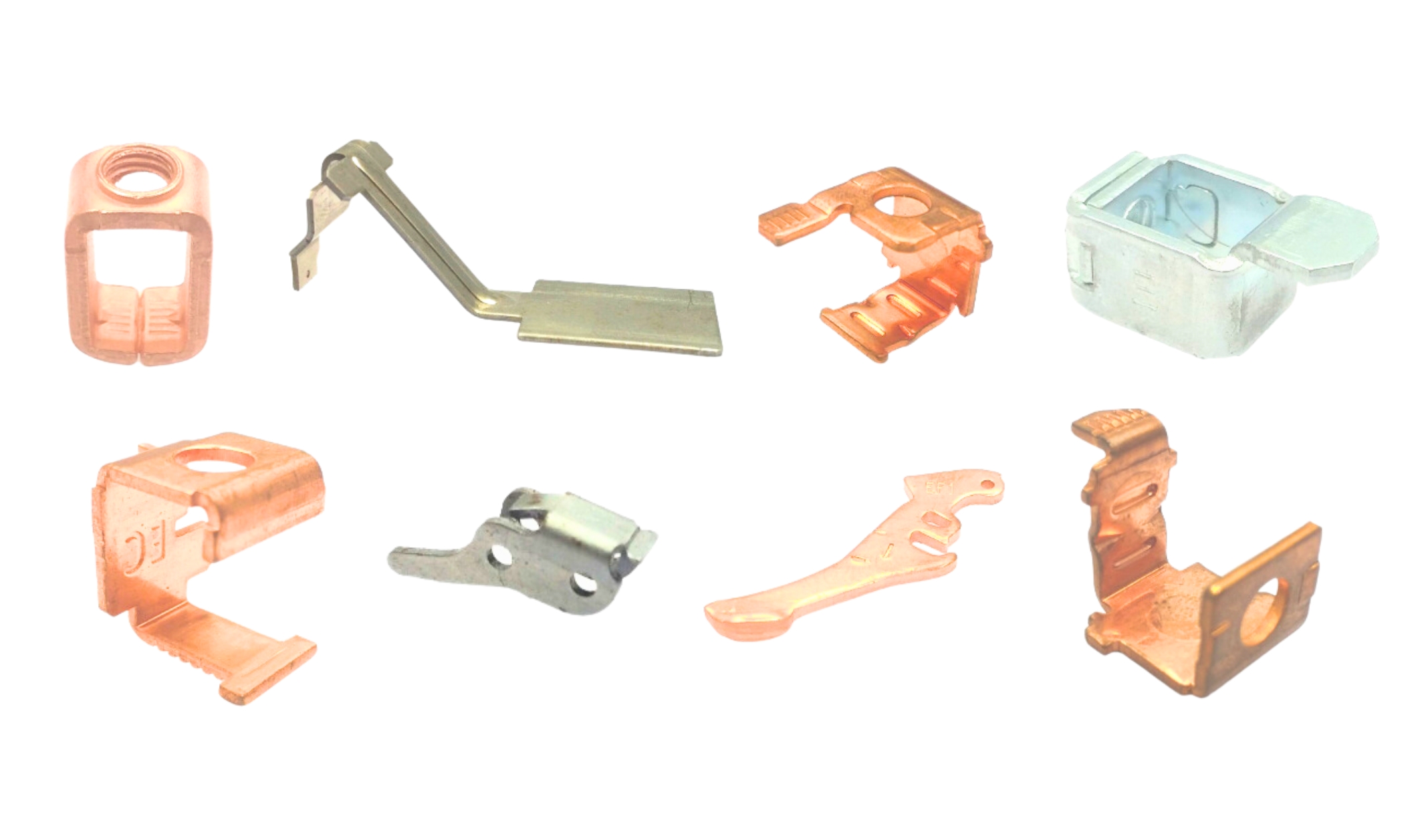

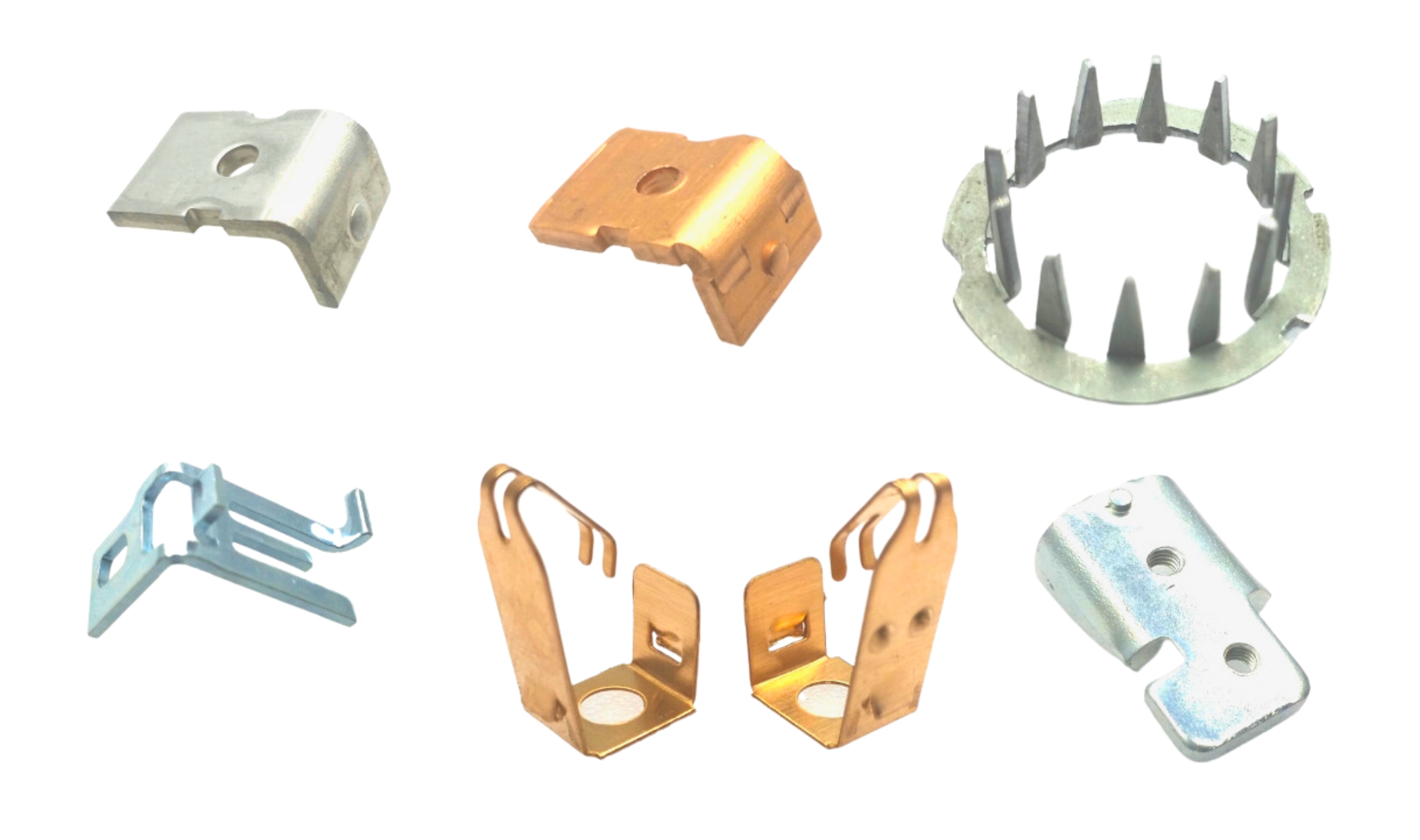

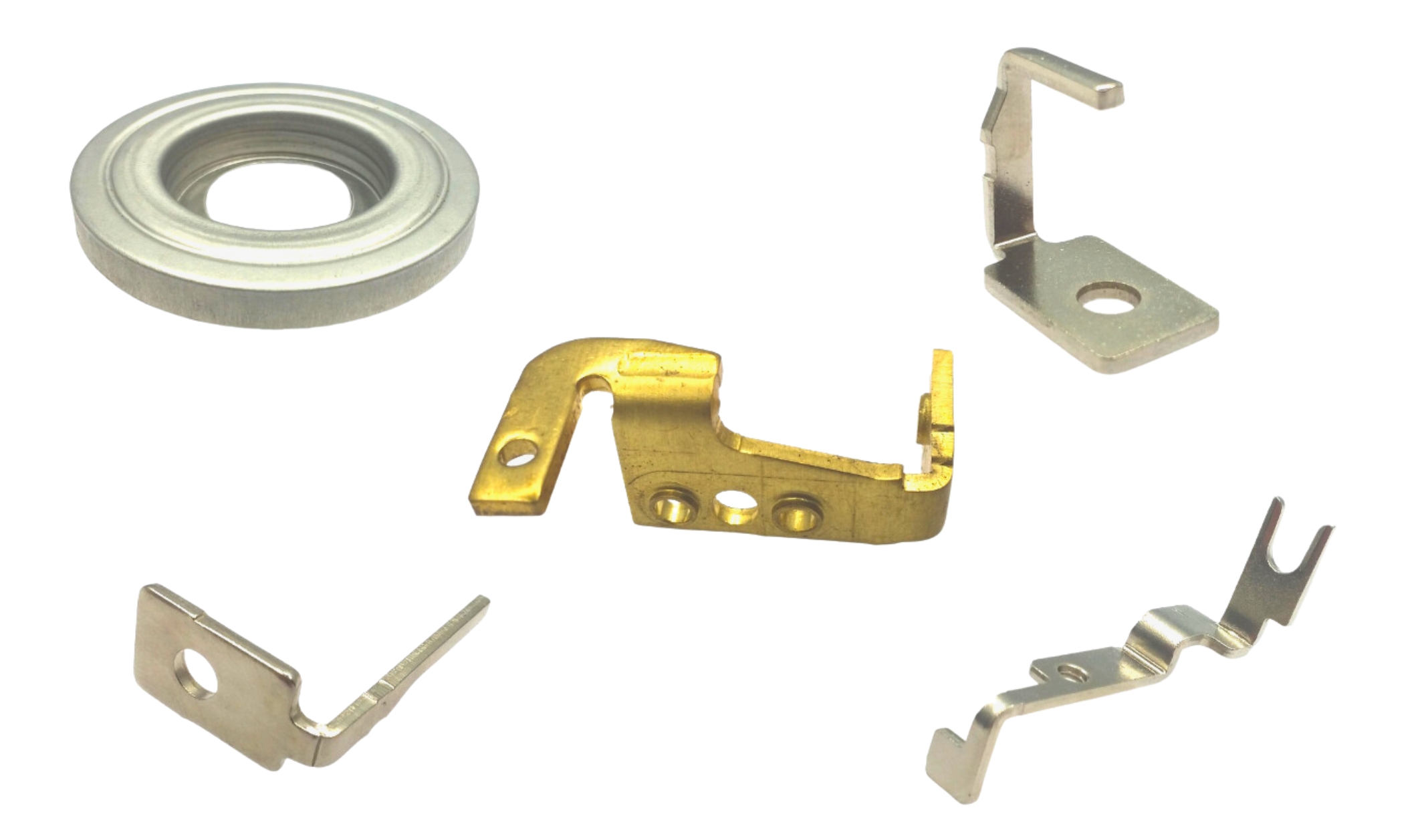

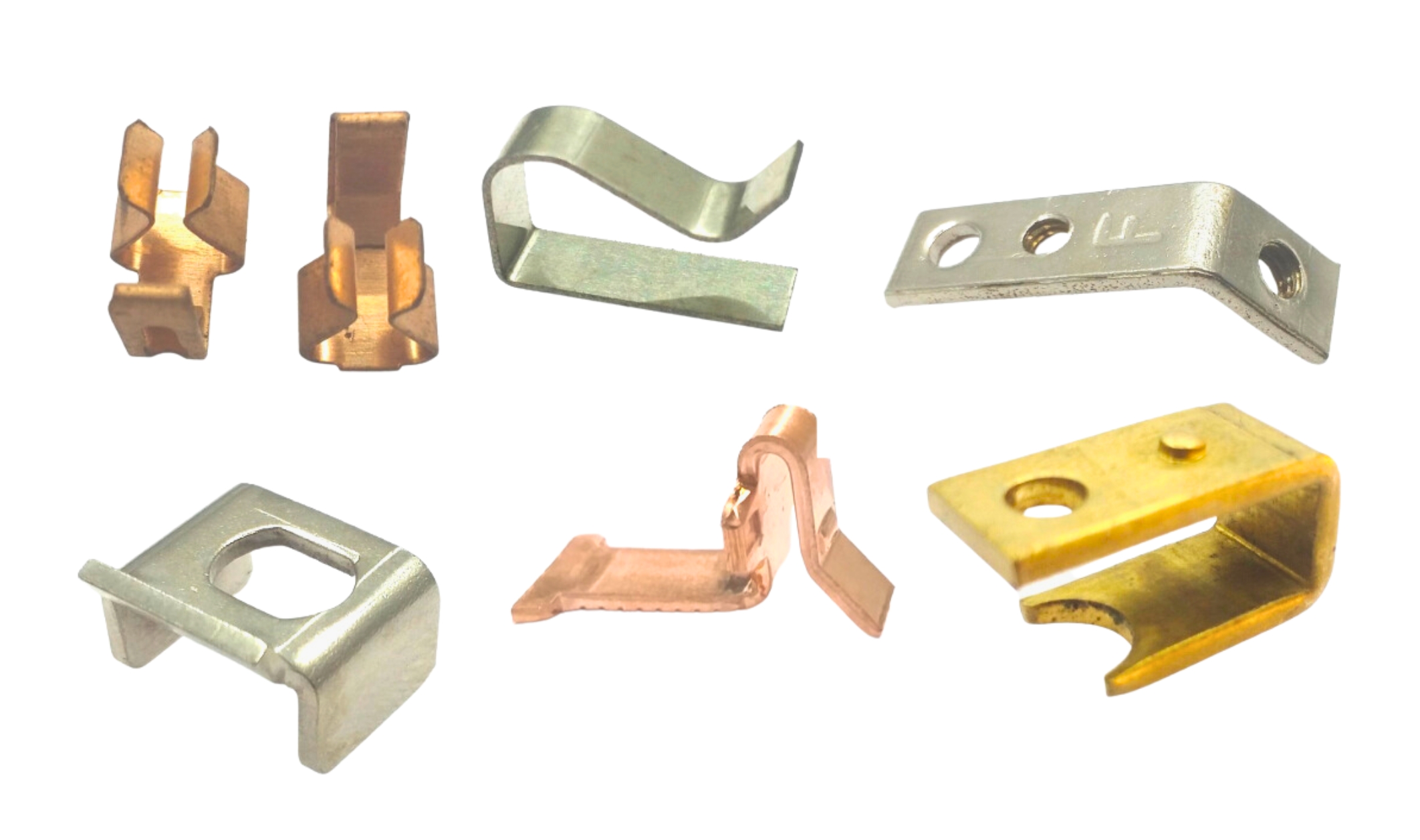

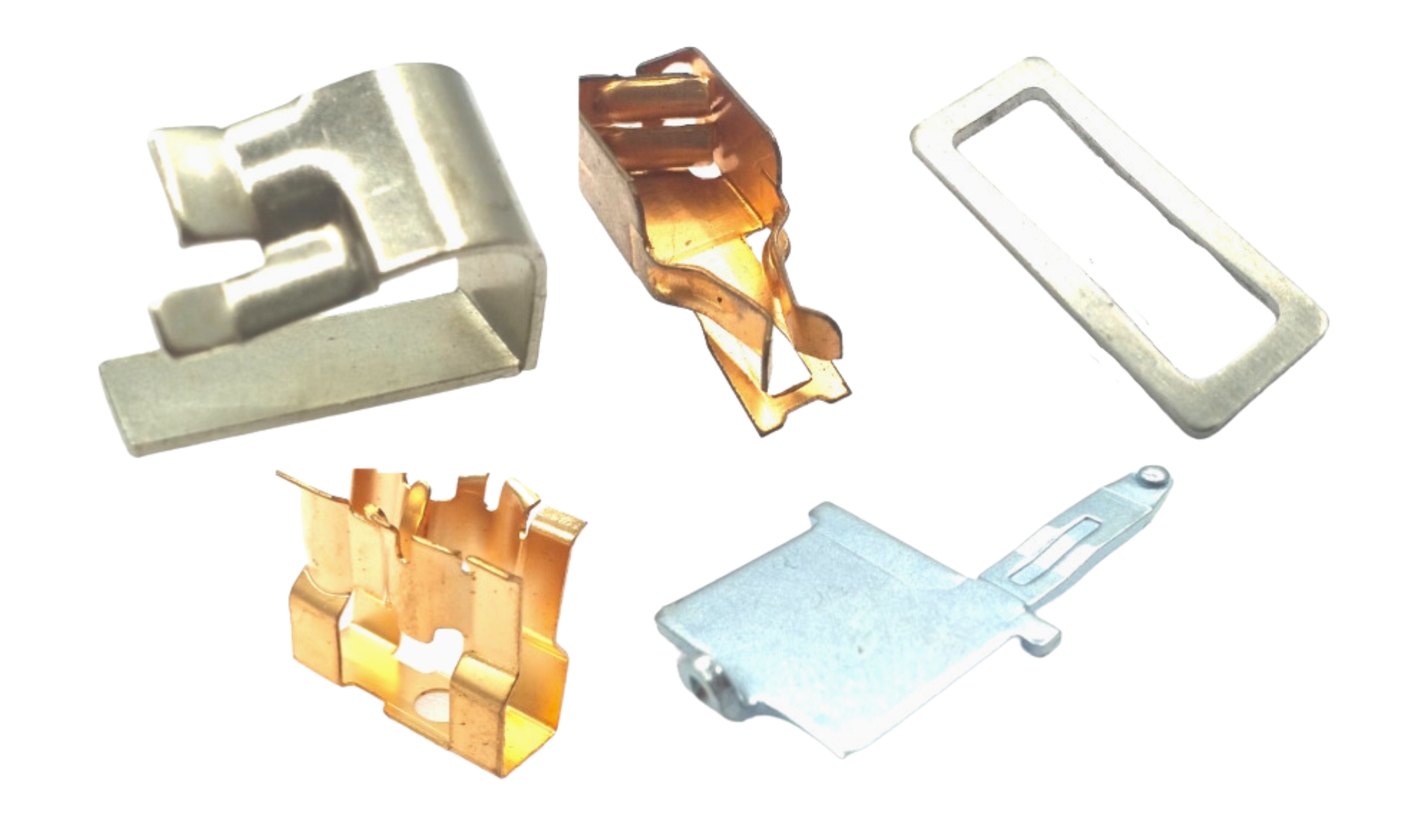

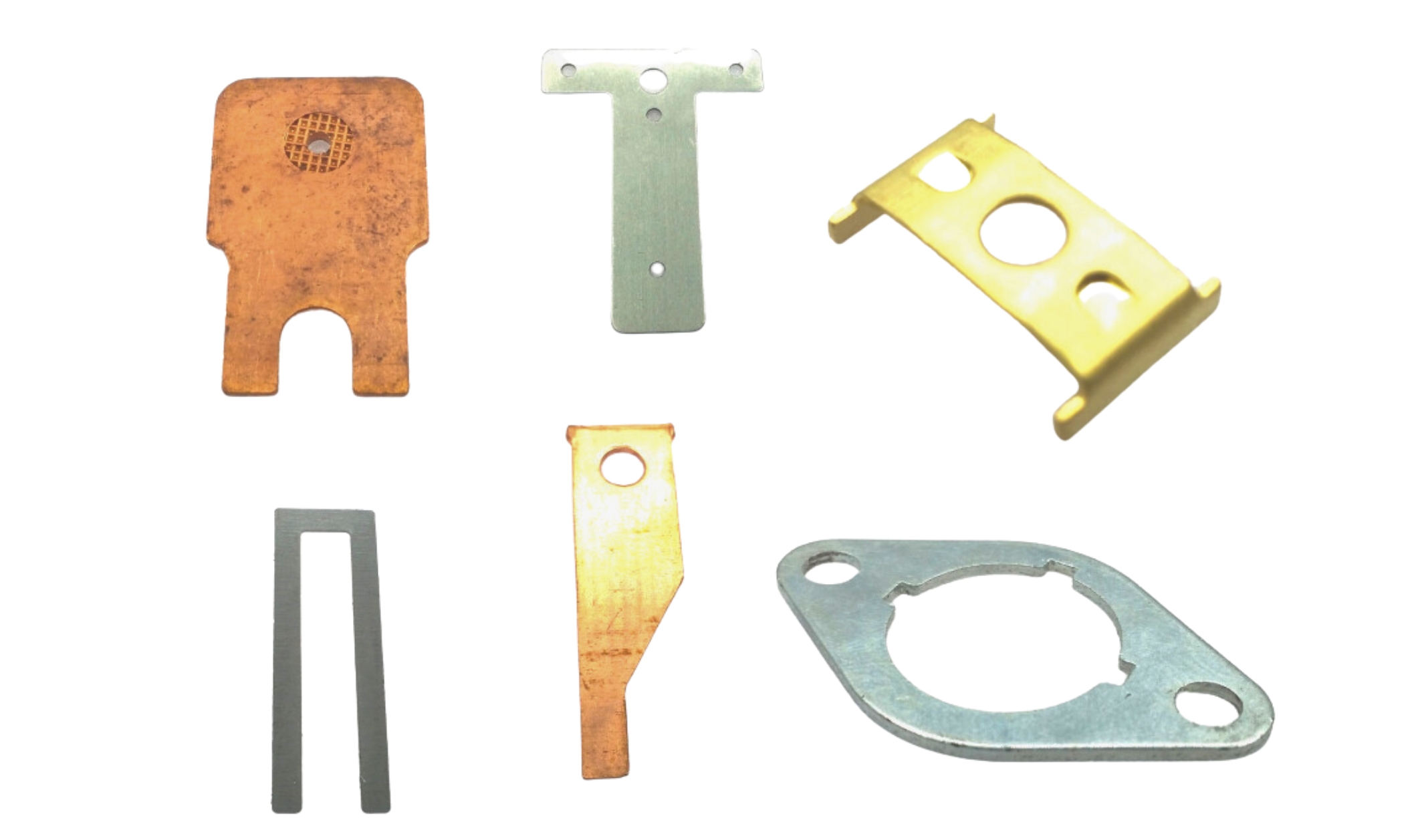

We work with a wide variety of materials in the precision metal stamping process, including Brass, Phosphorous Bronze, Stainless Steel, Copper, Beryllium Copper, Cold Rolled Steel, Aluchrome, and Nikrothal, with thickness ranging from 0.18mm to 3.0mm. This allows us to provide metal stamping services and products for a diverse range of industries, including Lighting / Electrical and electronics / Industrial engineering and Automation / Automobile / Consumer Durables.

In addition to our precision metal stamping capabilities, we also offer a comprehensive range of secondary processes, including tapping, welding, stacking, and mechanical assembly. This ensures that our customers receive a complete solution that meets their specific requirements and exceeds their expectations.

At Electroforce, we are committed to providing our customers with exceptional quality, reliability, and service.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat labore et dolore magna aliqua.

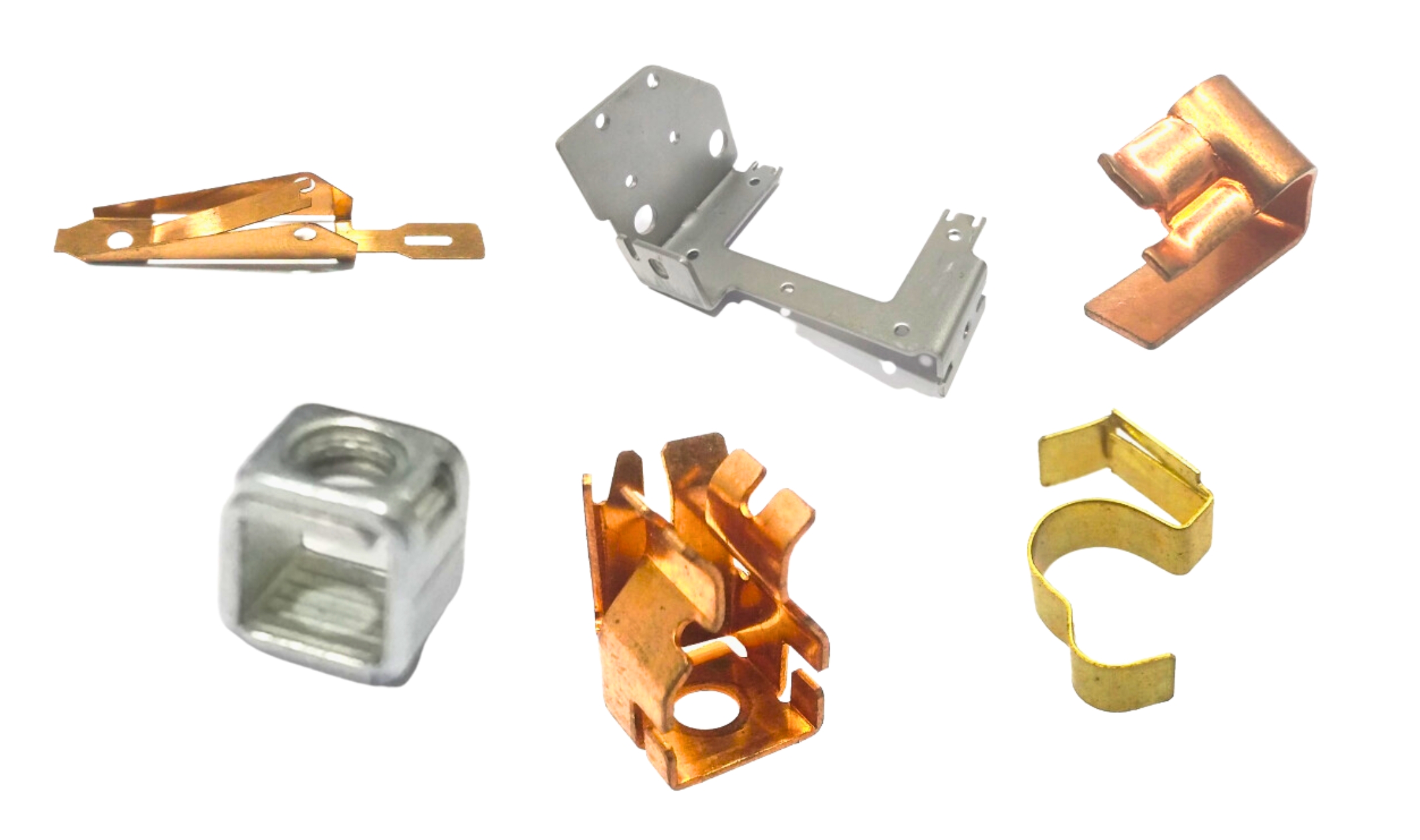

At Electroforce, we specialize in providing high-quality, high-volume, tight-tolerance metal stamping services. We understand that the development of electrical components requires a delicate balance between high accuracy and cost-effectiveness.

To meet the needs of our customers, we utilize state-of-the-art Multi-slide Sheet formers, which enable us to reduce wastage and manufacture complex parts with difficult geometries in an economically feasible manner, even in large quantities.

Our Multi-slide Sheet formers are capable of sheet metal forming with installed capacities ranging from 10 Tons to 26 Tons, ensuring that we can provide precise and efficient solutions for a wide range of requirements.

Class – A Progressive Die Tooling

At Electroforce, we take great pride in designing and building tooling of the highest quality for our precision metal stampings.

We have the capability to produce tools in a wide range of sizes, from as small as 75 x 75mm to as large as 1000 x 450mm.

Tool Construction

Artemis Complex,

39/5, Mauje Waliv Vasai (East) Thane, Maharashtra – 401208,

India

© 2023 Electroforce India | Powered by RVision Digital